Fiberglass Silicone Sleeving 1.5kV

GF-15

Product Introduction

1.5KV Fiberglass Silicone Sleeving

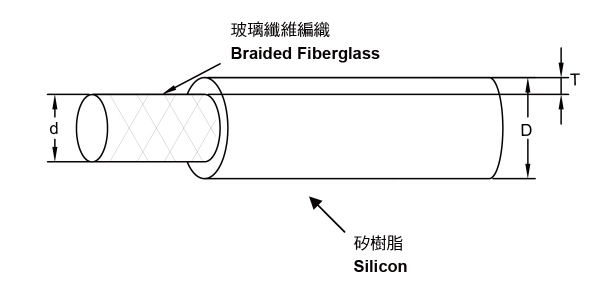

is a flexible, high-temperature tubing made by braiding alkali-free glass fiber yarn and coating it with silicon resin. It has excellent electrical insulation properties, a breakdown voltage of 1.5KV, and is flame-retardant, making it ideal for use in wiring harness insulation for H & N class motors, household appliances, electric heating equipment, special lamps, televisions, and electronic instruments. This sleeving is compliant with UL, RoHS, REACH, and halogen-free regulations, ensuring its safety and environmental sustainability. Its superior heat resistance of up to 200℃ makes it suitable for use in high-temperature environments.

Feature

- Material: glass fiber silk, silicone resin

- Temperature range: -10℃ ~ 200℃

- Breakdown voltage level: 1500V

- Flame retardant grade: VW-1

- Color: White, Black, Red.Customized Colors are also acceptable.

Video

Product Introduction

The Use Of Fiberglass Silicone Sleeve:

Using the fiberglass silicone sleeve to protect wires and cables, provide performance such as insulation resistance, high-temperature resistance, and self-extinguishing properties. The fiberglass silicone sleeve is made of alkali-free glass fiber yarn braiding into a tube greige and coating with silicon resin by high temperature. Widely used in H-class motors or N-class motors, household appliances, electric heating equipment, special lamps, internal wiring harnesses of TVs and electronic instruments, etc.

Features of Fiberglass Silicone Sleeve

-

Temperature Resistant

The highest temperature resistance can reach 200°C; the lowest is -10°C, which is suitable for environments with harsh temperatures or for equipment that generates heat by itself, such as motors.

-

Flame retardant and self-extinguishing

It can reduce the occurrence of accidents. The fiberglass silicone sleeving has the features of flame retardant and self-extinguishing. Good Gi’s fiberglass silicone sleeving can meet the UL international certification VW-1 flame retardant and self-extinguishing standards. Work with you to create safe products and a working environment.

-

Withstand Voltage

It is suitable for the heavy electrical industry and motor industry. The tested breakdown voltage of this product can reach up to 4000V, and the dielectric strength is high. Good Gi also has the products with breakdown voltages of 1500V, 2500V, and 7000V for selection.

Coating Material of Fiberglass Silicone Sleeve:

Good Gi’s fiberglass Sleeving is all made of silicone coating, which is formed by braiding alkali-free glass fiber yarn into a tube greige and coating the surface with silicone resin by high-temperature treatment. The standard colors of fiberglass silicone sleeves are black and white and we have excellent abrasion and high-temperature protection. We also have UL, CSA, REACH, RoHs and other international third-party certifications.

How to choose the suitable size for fiberglass silicone sleeve?

-

Measuring the diameter of the bundle of cables you plan to cover.

-

The covering diameter should be smaller than the inner diameter on the specification sheet.

Where and how to buy?

Please click here to contact Good Gi, please let us know what kinds of products and quantities you need. Please also share the application of products with us and we will provide our suggestions and reasonable quotations with you based on industry experience.

-

Over 30 years of manufacturing experience

-

Experienced manufacturing technology can adjust the production arrangement more flexibly and quickly.

-

Rich industrial experience, providing one-stop services and comprehensive purchasing channels.

-

Perfect management with high-efficiency and high-quality completion of punctual and fast delivery.

-

-

Strictly control the quality - In-house testing in our laboratory

It is the best choice to cooperate with Good Gi. We provide professional services and it is our responsibility to strictly control the quality. Referring to the characteristic parameters listed in the specification, Good Gi's own laboratory equipment is ready for real-time testing at any time. The Aging Oven Tester that can do long-term high-temperature aging test and melting point test; The low-temperature bending test machine can check whether the sleeving/tubing will break when bent at extremely cold temperatures; The constant temperature oil resistance test machine can perform constant temperature oil resistance test in accordance with ASTM specifications. It can test various oil bodies for vehicles, IRM test oil and ASTM test oil at constant temperature. For more laboratory equipment, please click here to get more information.

-

Quality Assurance

-

Made in Taiwan , Zero Defect Is Our Quality Goal.

-

Passed multiple third-party international certifications such as ISO, you can trust us when purchasing products from Good Gi.

-

Strict control and calibration of real-time tests in our own laboratory.

-

-

Regular Stock

Good Gi prepares regular stock to meet the temporary needs of users and sample needs.

-

Cost advantage

It’s more efficient to save costs when customers purchase products from manufacturers directly to get products faster and pay at affordable prices.

Certificate from the Third Party

Engineering Picture

Features

| {{ typeOne.merge }} |

|---|

| {{ itemOneTitle }} |

| {{ item }} |

Specifications

| {{ typeTwo.merge }} |

|---|

| {{ itemTwoTitle }} |

| {{ item }} |

| {{ typeThree.merge }} |

|---|

| {{ itemThreeTitle }} |

| {{ item }} |