How many types of cable glands are there? How to choose the size of Cable Gland?

2022-06-29|

Table of Contents |

How many types of cable glands are there?

In the market, there are many kinds of cable glands, and users can choose them according to the material or application, or also can consult the technical engineers of Good Gi Co., Ltd to assist in choosing suitable cable glands for their equipment.

Cable Gland by Material

-

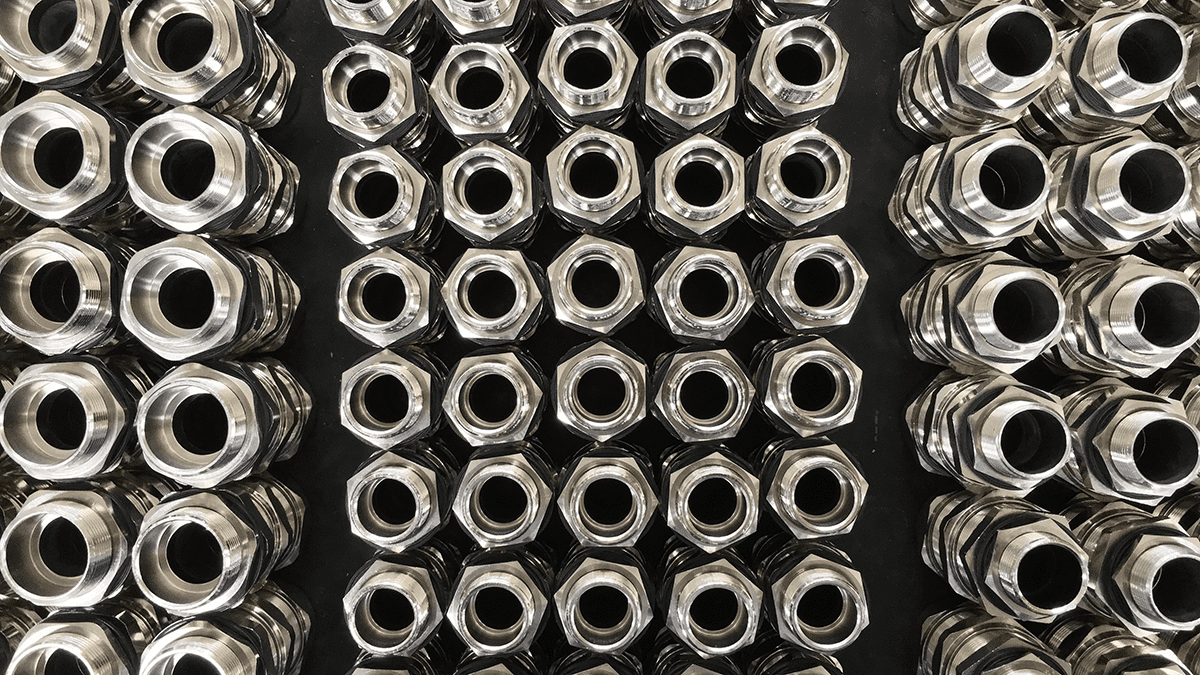

Stainless Steel Cable Gland

Stainless Steel is defined in GB/T20878-2007 with stainless steel and corrosion resistance as its main characteristics, with a chromium content of at least 10.5% and a maximum carbon content of no more than 1.2%.

Stainless Steel is the abbreviation of stainless acid-resistant steel, which is resistant to weak corrosive media such as air, steam, and water, as well as to chemically corrosive media (acid, alkali, salt, etc.).

It has excellent mechanical properties such as abrasion resistance and high hardness, but the processing cost is also high.

-

Copper Alloy Nickel Plated Cable Glands

Copper alloys are brass based on copper with other elements added. Brass has strong wear resistance, high mechanical strength, high hardness and strong chemical corrosion resistance.

-

Zinc Alloy Nickel Plated Cable Gland

Zinc alloy is an alloy based on zinc with other elements added. Zinc alloy has low melting point, good fluidity, easy fusion welding and processing, corrosion resistance in the air, easy recycling and remelting of residual waste. But compared with copper and stainless steel, its strength is lower and more prone to aging to cause dimensional changes.

-

Aluminum Nickel Plated Cable Gland

Aluminum alloy is one of the light metal materials, with good electrical and thermal conductivity, good corrosion resistance, and weldability, can be used as a structural material, and has low loss for turning.

-

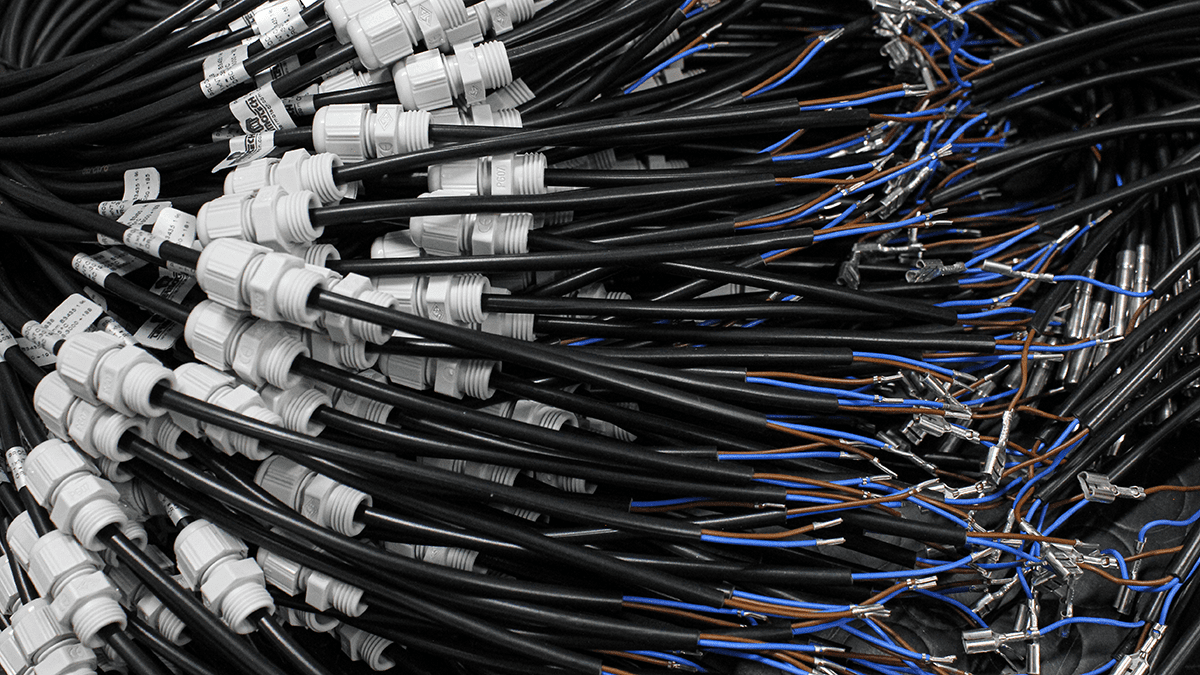

Nylon Cable Gland

PA Cable Gland has good comprehensive properties, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubrication, low friction coefficient, flame retardancy, easy processing. We can also add glass fiber and other fillers to improve the performance of cable gland and expand the application range.

Cable Gland by function

-

Flame retardant Cable Gland

When selecting metal cable glands, the metal parts are all flame-retardant. It should be noted whether the plastic parts are flame-retardant, such as clamping claws, clamping rings, gaskets, and UL flame-retardant is divided into 94HB, V-2 , V-1, V-0.

-

Torsion-resistant Cable Gland

The general tightening nut is changed to a spiral torsion-resistant structure, which can disperse the stress of the cable being pulled in applications where the outlet angle is large or the cable is often pulled.

-

Shielded Cable Gland

The cable gland is used as a conductor. When the isolation line or wire is installed, the metal shielding spring or metal gasket attached inside is used to contact the metal shielding braid in the cable and guide the electromagnetic wave of interference to the grounding line. So that sources of electromagnetic interference can be evacuated.

-

Porous Cable Gland

It can be used with 2~8 cables, and each hole is also still with the effect of sealing, waterproofing and insulation, and will not be entangled with each other.

-

Armored explosion-proof Cable Gland

With thicker metal, it is used to fix armored cables, suitable for explosion-proof equipment, petrochemical, or automation engineering in dangerous environments.

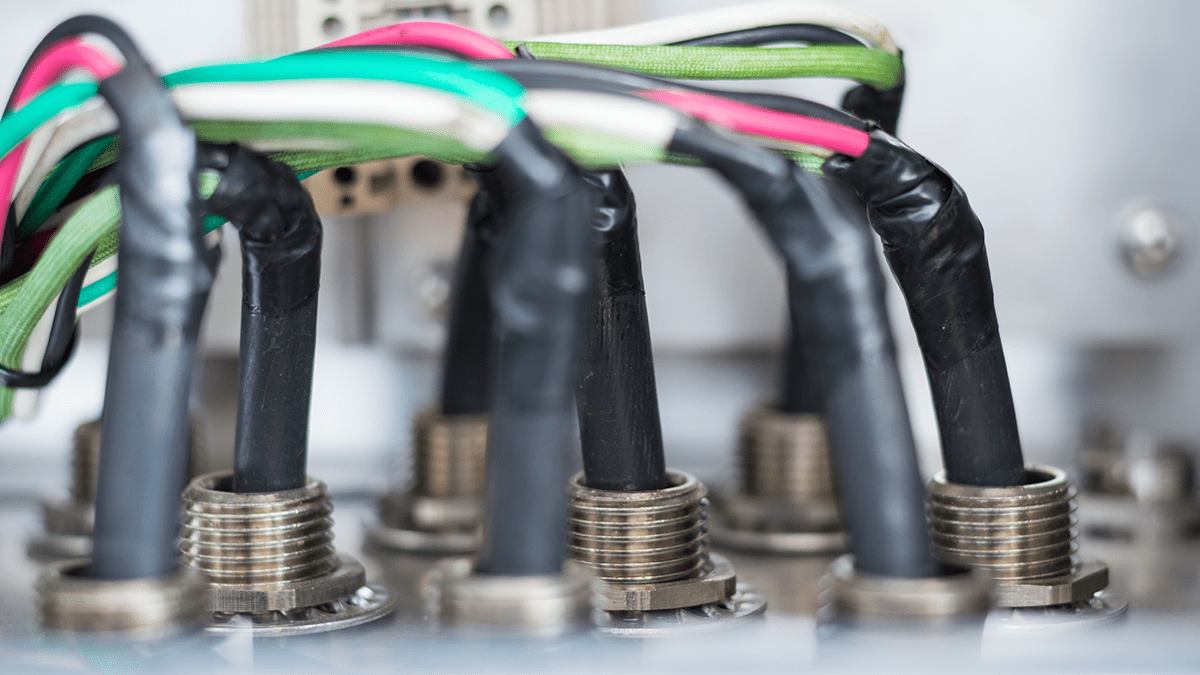

How to choose the size of the cable gland?

At first, make sure the inner diameter of the rubber inner plug is in line with the outer diameter of the wire and cable so that it can be completely sealed with the cable gland and has sufficient tensile strength.

Then ensure that the length of the joint thread is enough to pass through the locking nut on panels. Good Gi Co., Ltd. provides short threads for faster locking when used on thin panels as well as long threads for thick panels.

If the hole of the board is with tapped thread, it is necessary to confirm which kind of tapped thread of the hole is. Commonly there are M tooth, PG tooth, G tooth, and NPT tooth. Finally, confirm that the outer diameter of the joint will not interfere with the structure of the equipment.